As a home owner, installing a security window or door is pretty straight forward – you contact a security fabricator, they install the security door or window and your home is secure!

We all know stainless steel mesh is an important component of security windows and doors.

But did you know slight differences in the techniques and procedures used by suppliers to manufacture this mesh, can equate to significant differences when it comes to the performance of the mesh?

Let’s explore some of the factors that affect the quality and performance of stainless steel mesh used in security windows and doors.

There are hundreds of suppliers of stainless steel mesh around the world, claiming to have the highest quality mesh at the most affordable prices. It would be quite a challenge for any security fabricator to compare the various suppliers and the quality of the mesh they manufacture.

There are a number of important attributes to consider when analysing the quality and performance of stainless steel mesh including:

*Raw materials and wire composition

*Weaving techniques and equipment

*Powdercoat finish

*Testing and compliance

*Regular cleaning and maintenance

WHAT’S THE DIFFERENCE BETWEEN 304 AND 316 MARINE GRADE MESH?

Wire composition

As you probably already know stainless steel mesh is made of intersecting columns of stainless steel wire. This type of mesh has been around for centuries and is used in a number of applications such as fencing, barricading, grills, sifters and metal safety gloves.

As mentioned previously, the type of marine grade stainless steel is an important factor to consider because of its chemical composition and marine grade 316 is considered the superior mesh because of its higher corrosion resistance.

With the increasing popularity of 316 marine grade mesh, it has never been more important to reassure customers of the quality of the mesh used in their security products. It is for this reason, Darley send samples of our screenguard mesh to third party laboratories to verify the chemical composition of our stainless steel mesh and ensure customers receive quality 316 grade stainless steel.

Another aspect that needs to be taken into consideration is the diameter of the wire used in the stainless steel mesh. In Australia, the two most common wire diameter sizes are 0.8mm and 0.9mm. Our ScreenGuard system uses wire with a diameter of 0.8mm. The same wire diameter has been used in the manufacturing of ScreenGuard mesh for over 15 years, offering consistent quality and appearance but also making it slightly challenging in the weaving process with thicker wire being harder to weave.

As you probably already know stainless steel mesh is made of intersecting columns of stainless steel wire. This type of mesh has been around for centuries and is used in a number of applications such as fencing, barricading, grills, sifters and metal safety gloves.

As mentioned previously, the type of marine grade stainless steel is an important factor to consider because of its chemical composition; marine grade 316 is considered the superior mesh because of its higher corrosion resistance.

Another aspect that needs to be taken into consideration is the diameter of the wire used in the stainless-steel mesh. In Australia, the two most common wire diameter sizes are 0.8mm for 316 marine grade mesh and 0.9mm for 304 marine grade mesh. Our ScreenGuard system uses wire with a diameter of 0.8mm. The same wire diameter has been used in the manufacturing of ScreenGuard mesh for over 15 years, offering consistent quality and appearance but also making it slightly challenging in the weaving process with thicker wire being harder to weave.

The tensile strength of the individual steel wire is an important contributor to the strength of the stainless-steel mesh. Tensile strength is the measurement of force the wire can withstand before it breaks. The stainless-steel mesh used in the ScreenGuard system has a tensile strength of 850 – 900 pascals. Meaning it can bear a heavy load before breaking – making it an ideal barrier in extreme weather conditions. It’s interesting to note – it is possible to increase the tensile strength of a single strand of stainless-steel wire. This process is referred to as quenching and involves applying a heat treatment to the wire, followed by rapid cooling – which alters its chemical properties and increases or decreases its tensile strength.

Weaving process

Having a high-quality wire is one of the most important parts of the process but this doesn’t mean anything if it’s not combined with an effective weaving process.

There are generally 2 ways of combing metal wire to create a sheet of mesh:

-a welded wire mesh process

-a woven wire mesh process

The welded wire process for creating mesh is made using an automatic type welding machine that welds intersecting wires together to create a permanent bond. While the woven wire mesh process uses a specialised machine and a spinning technique that shoots out the wire in a fast-action motion to create the mesh.

Our ScreenGuard stainless steel mesh uses the woven method, which relies on the precision of specialist machines. These machines are precision engineered, German and Japanese made machines that shoots out the wire in a fast moving action to create the weave pattern and also sets the size and shape of the hole aperture.

Consistency and appearance of the mesh

Quality is one thing, but we also want our mesh to have a flat, smooth and consistent appearance.

Not only is this aesthetically pleasing to the home owner but it also assists in providing protection from debris, pests and corrosion. The precision of the specialist weaving machines play a vital role in keeping the mesh smooth, flat and free of imperfections.

Powdercoating

We all know powdercoating is a type of finishing that is applied to a surface using a free-flowing dry powder. It is applied using an electrostatic process and then cured under heat.

Our ScreenGuard mesh is supplied powder coated black and is covered by our 10 year warranty.

To ensure a consistent and smooth powdercoat finish, the mesh should undergo a pre-treatment to clean and decontaminate the surface. Not all mesh suppliers apply a pre-treatment prior to powdercoating, which affects the longevity of the finish. ScreenGuard’s mesh suppliers always pre-treat the mesh, which rids it of contaminants such as oil, grease, surface corrosion and free floating particles.

Test Reports

Most security fabricators are familiar with the tests applied to security products under the Australian Standard AS 5039-2008. One of the tests used in the standard is the Knife-shear test, which is designed to imitate a knife attack from an intruder, where they attempt to cut through the mesh of the security window or door.

Our ScreenGuard security products have been tested for and meet Australian Standard AS5039-2008

passing the knife shear test, as well as, other compulsory tests including dynamic impact, anti-jimmy, child fall prevention, bushfire and fire attenuation.

In fact, the supplier of our ScreenGuard mesh goes one step further and applies their own knife shear and salt spray tests. Every time we receive a new batch of mesh from our supplier, they provide an independent knife shear test report and salt spray test report – which confirms over 1000 hours of testing with no signs of corrosion. Darley also conducts spot-check testing with a NATA accredited laboratory to provide a secondary level of QA screening.

Another important factor that needs to be taken into consideration is the actual installation of the security doors and windows. AS5039 is the standard that governs manufacturing of security windows and doors, while AS5040 is the Australian Standard that for installing Security screen doors and window grilles. This standard provides installers of security screen doors and grilles with specifications for installing security screen doors and window grilles used primarily in residential applications. If the security product is not installed correctly and according to these standards, then it is not considered secure.

Regular maintenance and cleaning

We have highlighted many factors, that influence the quality and performance of mesh – most of which are related to the manufacturing process. One very important contributing factor, influenced by the homeowner is regular cleaning and maintenance of security doors and screens.

It’s all good to discuss advanced manufacturing techniques but it means nothing if the homeowner doesn’t regularly clean their security screens to protect against corrosion. The frequency of cleaning is dictated by the type of environment the home is located in. Please refer to the table below for suggested cleaning frequency:

Most security screens can be cleaned using a soft bristled brush or cloth, warm water and a neutral detergent. With ScreenGuard, cleaning becomes even easier with ScreenGuard Powawash detergent. Its biodegradable, non-toxic – all you need is 3 caps (25mls) mixed with warm water to wash your security doors or screens.

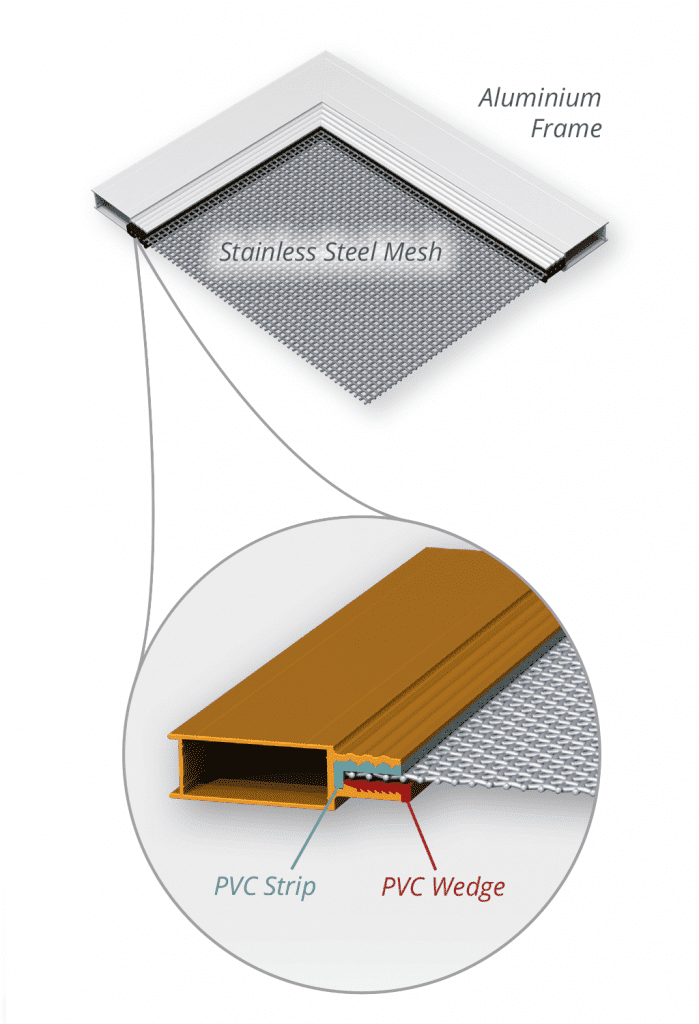

We’ve discussed the importance of the stainless steel mesh in our ScreenGuard security systems but we must not forget that the aluminium window or door frame, also plays an important role. ScreenGuard’s patented security system offers superior performance and protection thanks to the combination of its stainless steel mesh and premium grade aluminium frame. To find out more about ScreenGuard go to www.screenguard.com.au or contact your local Darley branch